The customised solution

3D printing helps to reduce costs and lead times as well as to increase productivity. All process steps of the Dreve dental 3D workflow interlock smoothly and ensure a consistently high quality.

Slicer Conversion to printable file

Dreve‘s own slicing software is used to create a printer-readable file from an STL file. The upload to the printer is direct and uncomplicated.

Print profiles The material “profile“

The print profile contains all the parameters necessary to process a resin on a specific type of printer, for example, exposure times. All print profiles were elaborately worked out and precisely set by the company‘s own process technology. Several profiles are available for each material – tailored to each application.

Materials FotoDent®

The FotoDent® product world offers you a wide range of materials for customized 3D printing resins for every dental need.

Printer Phrozen Sonic XL 4K

The devices calibrated in Unna with fixed factory settings implement all settings optimally. The large stainless steel build platform enables a high print volume with low acquisition and maintenance costs at the same time.

Cleaning FotoWash

The washing unit effectively removes excess resin adhering to printed components after the printing process.

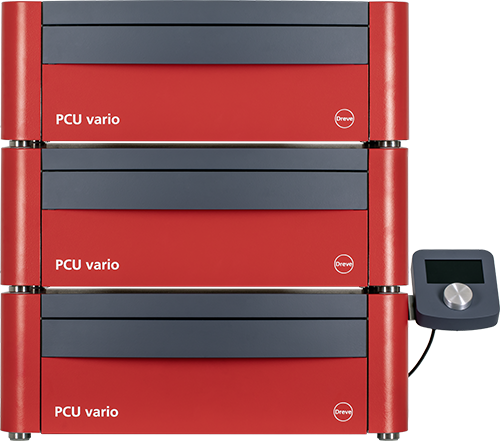

Post-curing PCU vario, PCU LED N2

Crucial for the perfect result: a powerful light curing unit! For the validated process, the components must be post-cured after cleaning so that the final material properties can be set.

NEW! Phrozen Sonic XL 4K

Compact LCD desktop printer with 52 μm printing precision thanks to 4K display and high light intensity for fast build times. High-quality processed full metal housing, large installation space and easy tray handling make the Dreve version of the Sonic XL 4K a user-friendly 3D printer for all dental applications.

+ Building platform with optimal adhesion properties

+ Customized software with precisely adjusted pressure profiles

+ Technical Service by Dreve

+ Dreve ElementS slicer and optimized print profiles

NEW! FotoWash

Cleaning unit for 3D printed components after the printing process. Unit with magnetic stirrer technology and automatic transfer between the two basins. Various cleaning programs can be selected and created via the touchscreen. The platform of the Sonic XL 4K can be hooked directly into the unit and cleaned together with the adhering components.

+ Customized cleaning profiles for the FotoDent® materials

+ Optimal complement for the Sonic XL 4K

+ Automatic transfer between pre-cleaning and post-cleaning

+ Technical Service by Dreve

NEW! PCU vario

LED-based laboratory device for curing 3D printed components. Ensuring mechanics and biocompatibility through effective deep curing. The PCU vario offers both the option of a vacuum atmosphere as well as the option of curing under nitrogen. Biocompatible curing without inhibition layer can be achieved.

+ Modular design with up to 3 polymerization chambers

+ Open system with 30 freely programmable memory locations

+ Logging and monitoring of process parameters

+ Nitrogen and vacuum atmosphere possible

Our experts

DIY: Having decided for 3D printing is an innovative step for your workflow. However, sometimes especially the implementation and getting started can be challenging, not only for beginners. Our experts for dental additive manufacturing and 3D print are glad to support you on your way. They guide you through the process so that you will succeed and get your parts printed.

Sonic XL 4K

Support

Materials